Birth of a legend

Beer in Pilsen used to be brewed alternately by individual burghers with brewing rights. The quality varied, so the burghers of Pilsen had the idea of setting up their own brewery to make good beer. On 5th October 1842 in the new Burghers’ Brewery the brewer Josef Groll brewed the first batch of the new Pilsen beer that would soon conquer the world.

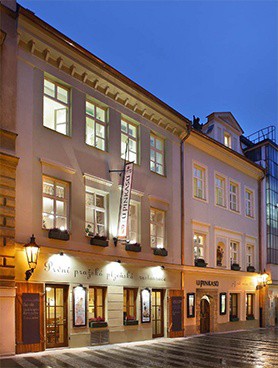

The first time in Prague at U Pinkasů

In April 1843 the Prague tailor Jakub Pinkas has his friend Martin Salzmann bring in two buckets of Pilsen lager. He falls for its magic, gives his original trade the boot and opens a pub. The beer proves so popular that the premises soon needed to be extended into the neighbouring building. The pub would later be visited by prominent figures such as Dobrovský, Palacký, Baťa and many more.

Bottom-fermented lager in Vienna, too

Pilsen beer makes it to Vienna for the first time. An even 65 buckets are delivered to Mr Josef Šedivý at 379 Salvator Street. The Burghers’ Brewery later becomes the official supplier to the imperial court; a storehouse opens in Vienna on 1st July 1870.

The Pilsner Bier trademark

As the popularity of Pilsen lager spread throughout Bohemia and the countries around, imitations started to appear. So, in 1859 the Burghers’ Brewery had “Pilsner Bier” registered as a trademark, although this is also used by other beers from Pilsen.

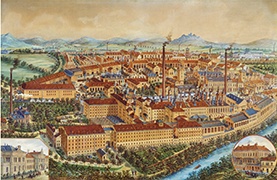

Brewery founded

The Gambrinus brewery was founded in 1869 by twenty prominent entrepreneurs led by Emil Škoda. A year later, on 15 October, the First Pilsner Joint-Stock Brewery (today Gambrinus) started its operation. The first trademark, Erste Pilsner Actien Brauerei – Pilsner Bier, was registered later in December.

First export to the New World

Both the Burghers’ Brewery and the First Joint-Stock Brewery celebrate their first successful exports to the USA in the same year. A year later Pilsner lager is being exported regularly to North America, and by the end of the 19th century has reached Latin America, Africa and the Middle East as well.

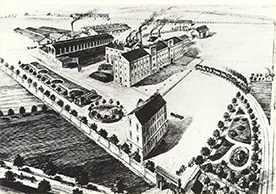

Velké Popovice Brewery founded

František Ringhoffer buys a brewery with a mill, fermenting cellar and malt kiln for his estate in Kamenice, and founds the Velké Popovice Brewery. The first 60hl batch of beer sees the light of day on 15th December. One year later and the brewery is producing 18,000 hl, a figure which increases to 80,000 hectolitres of beer after extensive reconstruction work in 1902.

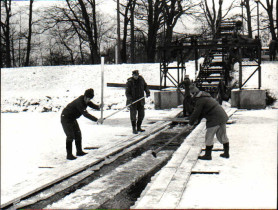

Ice cutting

The Burghers’ Brewery starts bringing in ice from the dam of the Bolevecký pond to deposit in its lager cellars, where the melting ice and cold air keep the entire cellar cool. The stocks of ice are stored in the courtyard on an insulated base made of wood, ash, sand, and tar-painted cardboard. The guided tour of the Pilsen brewery now features an exhibition on this “ice age”.

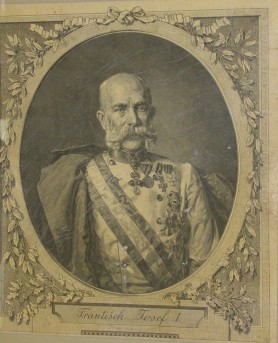

Franz Josef I at the brewery

“It is rather odd that no brewery has been able to duplicate the singular and delicious taste of Pilsner beer,” says Emperor Franz Josef I in praise as he visits the Burghers’ Brewery. The neighbouring First Joint-Stock Brewery is also flourishing: its premises are expanding and it is buying railway wagons for exports.

Bottling beer

The Burghers’ Brewery starts to bottle some of its lager. The First Joint-Stock follows suit and launches its bottling plant a year later. In response to the growing demand for bottled beer, in 1899 the Burghers’ Brewery builds its first bottling plant, which will keep running for the next 70 years.

Historic gateway

The Burghers’ Brewery celebrates its 50th anniversary, and to mark the occasion builds the Jubilee Gateway, which becomes the symbol of the brewery, the firm and the Pilsner Urquell brand. In 2000 period materials are discovered in the gateway, and documents describing the modern history of the brewery are walled up in it as a message to future generations.

Transporting beer

By 1876 the Burghers’ and the First Joint-Stock Brewery are leasing and later purchasing their first railway wagons from the State Railway. They also set up their own railway siding to replace the horse-drawn carriages. The Burghers’ Brewery buys a locomotive in 1895. By 1914 the brewery owns 388 wagons as well as its first cargo truck and car.

The immutable flavour of Pilsner Urquell

Pilsner Urquell takes pride in its consistent flavour, a fact that has also been confirmed by expert analyses. Measurements conducted by a Swiss laboratory in St. Gallen in 1897 record the qualitative parameters of Pilsner Urquell beer. The same results were also confirmed by its successor Labor Veritas in 2008. To this day Pilsner Urquell retains the same flavour that has made it so famous around the world.

Pilsner Urquell trademark

The General Customs Office in London had already designated Pilsner Beer as a special type of beer, regardless of its origin. So, the Plzeňský Prazdroj – Pilsner Urquell trademark was registered in 1898 to protect the unique brand which serves as the model for all Pilsner-type beers.

Refrigerated beer wagon

At the World Exhibition in Paris the Burghers’ Brewery presents its model refrigerated beer wagon. It soon has 258 of these wagons and from 1900 the ‘beer train’ starts to make the run from Pilsen to Vienna every morning. A similar train is soon carrying beer to Bremen, where they are loaded onto ships for the U.S. markets.

Spalek project

In 1904-1907 the Burghers’ Brewery carries a grand project, which will make it self-sufficient in supplies of electricity and water for decades to come. The Spalek project includes a generator station, wells in the Roudna waterworks, a de-ironing plant and a water tower. This serves as a reservoir for drinking and service water for most of the 20th century and becomes one of the dominant landmarks in the city of Pilsen.

Kaiserquell trademark

The beer produced by the First Joint-Stock Brewery is trademarked Kaiserquell, or Imperial Well, in honour of Emperor Franz Joseph I. In 1912 the Brewery is awarded the honorary title of “C.K. court supplier” and just before the First World War becomes the leading beer producer in Bohemia, with an annual output of more than 270 thousand hl of beer.

One million hectolitres of Prazdroj

The production of Pilsner lager passes the magical threshold of one 1 million hectolitres. The Burghers’ Brewery becomes the largest brewery and Europe and purchases its first cars. Before the First World War it has sales offices in 34 countries, including the U.S. and Egypt, and has been awarded a number of international medals.

Plzeňský Gambrinus

Kaiserquell, a trademark registered in honour of Emperor Franz Joseph I, no longer makes sense with the establishment of the independent Czechoslovak Republic. A new trademark is therefore registered, Plzeňský Gambrinus. The name Gambrinus dates back to the 13th century and is a corruption of the name of Duke Jan Primus, grandfather of Charles IV and the patron saint of brewers.

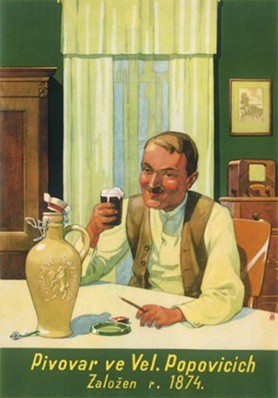

Registration of the Kozel brand

Kozel becomes the official registered trademark of the Velké Popopovice Brewery. This designation originates from a corruption of the Lower Saxony town of Einbeck, made famous in the 14th century for making bottom-fermented beer. This spread to Bohemia under the name Ein Bock (a goat – ‘kozel’ in Czech). The brewery emblem was created by an itinerant French painter in gratitude for the hospitality shown to him by the founder Ringhoffer.

Reconstruction of the brewhouse

Burghers’ Brewery completes the reconstruction of its brewhouse, which remains in use until 2004. A new building rises from the foundations of the original one: reinforced concrete storage silos are built and the brewhouse receives a 50 m high chimney with an integrated heater to make use of the heat that is emitted. New, more efficient automatic conveyor belts powered by an electric motor are installed underneath the kettles.

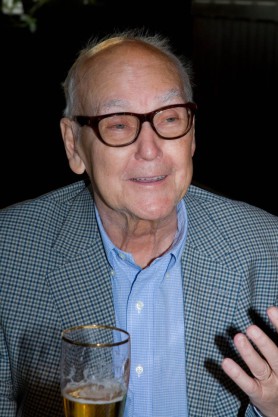

Hlaváček Dynasty

František Hlaváček becomes the managing director of the Pilsner Joint-Stock Breweries, making him the first of three generations of his family (more than 80 years) to link his name to the Gambrinus Brewery. His son, Ivo Hlaváček (pictured), was the chief brewmaster from 1958 to 1987 and later the production director; his grandson, Jan Hlaváček, worked in the Pilsen Brewery and Gambrinus Brewery from 1978. He is now the Brewer Emeritus for Plzeňský Prazdroj.

Developing transport kegs

In 1936, Pilsner brewmaster Štěpán receives an offer from the Škoda Works to buy modern aluminium barrels to transport beer in. Beer continues to be hauled to pubs in wooden barrels until the mid-1950s, when until these are replaced by aluminium barrels. These aluminium barrels will in turn be replaced with stainless steel kegs at the end of the 1980s. Large wooden barrels are used today for producing small volumes of Pilsner Urquell in the cellars of the Pilsen brewery.

Wartime stagnation

The Second World War interrupts the growth of both Pilsen breweries. The fleet park is confiscated by the Reich military administration. The U.S. boycotts Pilsner Urquell as a German product, and so exports the war are directed exclusively to Germany. The Gambrinus Brewery suffers a shortage of raw materials, which has an impact on quality. It makes a weak wartime “eight-degree” beer and only survives by supplying the Škoda workers with beer.

Cutting ice in bulk

A successful brewery needs large quantities of ice to preserve its beer. In the 1920s Plzeňský Prazdroj gets through 600 wagons of ice to make and preserve 400 thousand hl of beer. An iron conveyor is added in 1942 to improve the extraction rate, which increases to 100 tons of ice per hour. The last block of ice for the Pilsner lager cellars was extracted in 1987.

Bombing of the breweries

The Allied bombing raid of 17th April badly damages the cellars, brewhouses, fermentation rooms, bottling plant, and the residential houses of the Burghers’ Brewery; the Gambrinus Brewery is almost destroyed. However, the brewery director of the time, František Hlaváček, has faith in a bright future. What rises from the ruins would go on to become the most popular beer in the country – light draught Gambrinus, and a year later the newly constructed brewery would brew 200 thousand hl of high-quality beer.

Gambrinus has new steel tanks

Right from the very beginning the Gambrinus Brewery has invested in operations and technical innovations. At the end of the 1950s it installs 20 steel lager tanks with a capacity of 3 600 hectolitres. In March 1960 the first tanker truck leaves the brewery, and beer is bottled outside the brewery.

Technical innovations

Right from the very beginning the Gambrinus Brewery has invested in operations and technical innovations. At the end of the 1950s it installs 20 steel lager tanks with a capacity of 3 600 hectolitres. In March 1960 the first tanker truck leaves the brewery, and beer is bottled outside the brewery.

Establishment of the Radegast brewery

In 1965 the foundation stone is laid in Nošovice in northern Moravia for a new brewery to cater to the large number of demanding beer drinkers concentrated in the nearby industrial agglomeration. The first batch of beer is brewed on 3 December 1970. A year later the beer was given the name Radegast, after the ancient Slavic god of the sun, fire and hospitality.

Radegast gets its own malt house

The Radegast Brewery begins operating its own malt house, which at that time is the second largest in the country with an annual production of 24,000 tons of pale Pilsner malt. Thirteen years later Plzeňský Prazdroj also opened up a new malt house, with a capacity of 84 thousand tons of malt. This makes the brewery self-sufficient in the production of pale malt.

A million hectolitres of Gambrinus

The annual volume of beer produced by the Gambrinus Brewery passes the magical threshold of one million hectolitres. Although a directive passed by the authorities at that time intends Gambrinus for people living in West Bohemia only, the brand’s fame extends beyond this region. However, no one at the moment expects Gambrinus to become the most typical example of Czech beer.

A million hectolitres of Radegast

Radegast invests in the latest technology and is the first brewery in the country to introduce cylindroconical fermentation tanks. The volume of each of the 18 tanks is 2 000 hl. Annual production exceeds the magical threshold of 1 million hectolitres, a figure which will have increased to 2 million in another 10 years.

Birell non-alcoholic beer

The brewers of the Radegast brewery work with the Hürlimann brewery in Zürich, which has come up with radically new technology for making non-alcoholic beer using unique yeasts without interrupting the fermentation process. They refine the method, resulting in a full-bodied bitter flavour that would satisfy even the most hard-to-please Czech beer drinkers. Birell becomes the most popular non-alcoholic beer in the country.

Cylindroconical tanks at Gambrinus

Gambrinus starts to use cylindroconical fermentation tanks. In particular, these guarantee the microbiological purity of both the separate fermentation and maturation stages, thus ensuring that the beer has a pure flavour and the proper bite.

Pilsner Urquell Original Restaurant

In 1995 Prazdroj establishes a chain of restaurants that strictly observe the correct principles when storing, pouring and serving Pilsner Urquell lager and that properly care for its historical legacy. The first branch of the Pilsner Urquell Original Restaurant (PUOR) is opened in the Kolonáda Hotel in Karlovy Vary. This is followed abroad by restaurants in Moscow, Düsseldorf and Vienna, amongst others. The first PUOR in Asia opened in 2011 in Hanoi, Vietnam.

Brewhouse with the very latest technology

The Gambrinus Brewery launches a new brewhouse – the largest in the Czech Republic. The brewhouse is equipped with the very latest technology: environmentally-friendly and energy-saving, it also ensures the high and balanced quality of the beer brewed there.

A million hectolitres of Kozel

The Velké Popovice Brewery passes the million hectolitres per year mark, and is the fastest-growing part of Plzeňský Prazdroj. The installation of cylindrical tanks in 2004 increases production capacity to 1.5 million hl of beer. Interest in Velkopopovický Kozel also increases around the world. It is now the bestselling brand of Czech beer abroad.

Coopers’ craft and new bottling plant in Pilsen

After a gap of nearly 40 years, the cooper apprenticeship program is resumed, followed a year later by the opening of a new coopers’ workshop. This makes Prazdroj one of the last places in Europe to keep this traditional craft alive. Thanks to the coopers who take care of the barrels and vats, the brewery still produces a small amount of Pilsner lager in the same way as in 1842. This enables the brewers to compare whether beer brewed the modern way still has the same flavour.

The new Plzeňský Prazdroj bottling plant starts up in November. This, the largest ever investment made by the Plzeň-based brewery and amounting to roughly 1 billion crowns, is part of a comprehensive project aimed at expanding production capacity in order to meet the growing demand abroad. The new bottling plant is also used for other Plzeňský Prazdroj brands.

Tours of Plzeňský Prazdroj

The new tour takes visitors around the places authentic places where the legendary Pilsner lager was born. The tour includes a chance to taste unfiltered and unpasteurized Pilsner Urquell drawn straight from oak casks in the historical brewery cellars. In the first year alone the tour was taken by almost 150 thousand visitors.

Tours of Velké Popovice

The Velké Popovice Brewery is building a new tour, with a visitor centre and gift shop. This is in response to growing public interest in learning more about the tradition of Velkopopovický Kozel and how it is made. The tour includes a visit to the historical and modern brewhouses, as well as a beer-tasting session, of course.

Pilsner Urquell Master Bartender

In the sixth annual competition to find the best Pilsner Urquell bartender, the world title has finally gone to a Czech national – Lukáš Svoboda. The Pilsner Urquell Master Bartender is an international competition open to all taproom staff and bartenders who share a passion for their craft and for Pilsner lager. To get through to the final competitors have to demonstrate their knowledge, wit, language skills and charisma. More than 16,000 bartenders have entered the competition since it began five years ago.

Beer for the Vatican

The Easter batch of Pilsner Urquell lager, blessed by the Bishop of Pilsen František Radkovský, arrives on the papal See in the Vatican, as a gift from Plzeňský Prazdroj, the City of Pilsen and the Czech Republic to mark the beatification of Pope John Paul II. There, it is presented to the Vatican Prime Minister Cardinal Giovanni Lajolo by the Czech Ambassador to the Holy See, JUDr. Pavel Vošalík.

Kingswood cider

A new brand has hit the market – Kingswood, a cider brewed following the British tradition but adapted to suit Czech tastes. This new, refreshing alcoholic beverage is made from carefully selected ripe apples grown exclusively in orchards, which are never picked, but are all left to fall when they are ready. The secret behind this recipe lies in the careful selection of specific apple varieties and in the way they are blended.

New Genuinely Bitter 12° from Nošovice

The brewers of Nošovice have come up with a new beer, Radegast Genuinely Bitter 12°. This has replaced the former Radegast Premium light lager in the brewery’s portfolio. The new Genuinely Bitter 12° is fuller, and the three types of Moravian hop used give it a more intense yet pleasant bitterness and a distinctive hop aroma. 20 million half-litres of the new 12° were pulled within just the first three months of the beer coming onto the market.

Environmentally-friendly bus in Prazdroj

Since January 2015 visitors have been taken on the tour around the Plzeňský Prazdroj Brewery in Pilsen by a new bus running on compressed natural gas (CNG). This modern SOR BNG 10.5 bus in the Pilsner Urquell colours is powered by compressed natural gas (CNG), which greatly reduces emissions of carbon dioxide, nitrogen oxide and particulates in exhaust fumes.

Record-breaking brewery tours

In 2015 over 882 thousand visitors went on one of the tours or programmes prepared by Plzeňský Prazdroj in its breweries. The most popular destination was Plzeňský Prazdroj, which was visited by a record 750 thousand people. The brewery tours or events for the public at Velké Popovice were visited by 88 thousand people, while almost 44 thousand visitors came to Nošovice.

New bottling line in Pilsen

At Plzeňský Prazdroj, a new line for bottling beverages of different sizes was put into full operation at the end of June. This allows the consumer to choose, in addition to classic thirds and pints, cans ranging from two deciliters to one liter, as well.

Coopers heading to UNESCO

The traditional coopers’ craft is an inherent part of Plzeňský Prazdroj. The Pilsen brewery is the only one in the world that maintains this traditional profession and continues to employ coopers. Thus, in December 2018, cooperage was rightly registered on the national List of Intangible Elements of Traditional Folk Culture of the Czech Republic. It is therefore a further step towards the dream goal of being a UNESCO World Heritage Site.

New award of pubs - the Brewers' Star

Where should one go to make sure their draft beer has enjoyed the most excellent care? To places where they have the Brewers’ Star: a new comprehensive award, awarded in 2019 to pubs for their exemplary care for beer and perfect pouring. The best of the Czech Republic can be proud of this title for one year.

Prazdroj toasts To the Future!

Prazdroj has taken another very important step towards sustainability of its business. The company has undertaken to meet specific targets by 2030 – to be completely carbon-neutral in beer production, to reduce the use of plastic to a minimum, and to completely stop using non-recyclable types of plastic. The company will also make progress in further reduction of its water use – an area in which it is already one of the most successful companies.

The Start of the FOR HOPS Project

Changes in climate, weather fluctuations and especially unpredictable precipitation have in the recent years affected Czech hop farming. Hops are an ingredient without which Czech beer would never be as we know it. The FOR HOPS project, initiated by Prazdroj and bringing together experts from all over the world, came up with a solution. Using state-of-the-art technology, the project will help hop growers irrigate efficiently and save often scarce water. The aim is to maintain a sufficient quality and quantity for beer production in the future.

Termination of PET Plastic Bottle Use

Since the beginning of 2021, Prazdroj no longer uses PET plastic bottles, which means saving over 1,300 tonnes of plastic yearly. The beers of all our brands are now packaged only in kegs, tanks, glass bottles and cans.

Fully Automated Warehouse in Pilsen

More storage space and quicker dispatch of bottled and canned beer. This has been ensured thanks to the fully automated warehouse in our brewery in Pilsen since January 2023. It covers 10,000 m2, which equals 1.5 football pitches. With its self-supporting rack system and the other equipment used, it is the most modern Prazdroj warehouse and one of the most modern warehouses of this type in the Czech Republic.